Two-component epoxy resins are widely used as high-performance adhesives due to their excellent mechanical strength, chemical resistance, and versatility across industrial applications. However, their performance depends heavily on proper curing, which in turn is influenced by the resin-to-hardener mixing ratio.

When curing is incomplete or improper, epoxy systems can suffer from reduced strength, poor durability, or complete failure. Detecting these curing issues using conventional inspection methods is often difficult. This is where Evolved Gas Analysis–Mass Spectrometry (EGA-MS) provides a powerful solution.

In this technical study, EGA-MS is applied to evaluate the curing behavior of two-component epoxy resins mixed at different ratios, offering clear insight into how formulation affects thermal and chemical behavior.

Why Use EGA-MS for Epoxy Curing Analysis?

EGA-MS enables real-time monitoring of gases evolved during controlled heating of a sample. This makes it particularly effective for:

Evaluating curing completeness

Detecting unreacted components

Comparing resin-to-hardener ratios

Establishing appropriate pyrolysis conditions

By observing thermal decomposition profiles, laboratories can quickly assess whether an epoxy system has cured correctly.

Background

Two-component epoxy resins consist of resin and hardener are versatile adhesives and widely used across diverse applications owing to their excellent mechanical properties and high chemical resistance. Yet, inadequate mixing or insufficient agitation can result in poor curing. In this report, two-component epoxy resins cured with varied resin-to-hardener mix ratios were examined using evolved gas analysis (EGA)-MS.

Experimental

A GC/MS system with a Multi-Shot Pyrolyzer directly interfaced to the GC injector was used for measurements. A deactivated metal tube (UADTM-2.5N) and a Vent-free GC/MS adapter were used to connect the GC injector to the MS detector. The examined adhesive was a room-temperature-curing two-component epoxy resin comprising a resin (primary component: bisphenol A diglycidyl ether; BADGE) and a hardener (primary component: isophoronediamine; IPDA).

The resin and hardener were mixed on a paper at 3:1, 1:1, and 1:3 of resin to hardener ratios followed by curing for 2 hours at room temperature. Among these, the mixtures with ratios of 1:1 and 1:3 successfully cured, while the mixture with the 3:1 ratio resulted in a viscous liquid without curing. Each cured resin’s surface was scraped or scratched using a cutter knife, and the collected sample was placed in an Eco-Cup. The Eco-Cup was then introduced into the pyrolyzer furnace and EGA-MS measurements were conducted.

Results

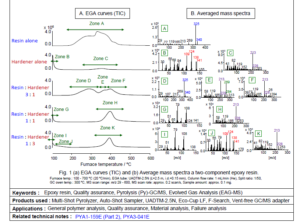

The EGA curves for the collected specimens are shown in Fig. 1(a). For both the resin alone and the resin-to-hardener ratio of 3:1, two peaks were observed in the temperature zones of 250–350 ºC and 350–450 ºC. For hardener alone and resin to hardener ratios at 1:1 and 1:3, a single peak was observed at 100 ºC and in the 350–400 ºC zone.

The furnace temperature for pyrolysis (Py)-GC/MS was determined to be 600 ºC based on the tailing of the peak derived from the polymer component in EGA curves. The next note (PYA1-159E) reports the result of the Py-GC/MS analysis of each collected sample.

To learn more about how EGA-MS and the micro-furnace pyrolyzer can be used to evaluate curing behavior and material quality of two-component epoxy resins, simply connect with us.

References: This technical note was developed by Frontier Laboratories Ltd. 4-16-20 Saikon, Koriyama, Fukushima, 963-8862 JAPAN. www.frontier-lab.com