Medium Density Fiberboard (MDF) is widely used in furniture, construction, and interior applications due to its uniform structure and cost efficiency. The performance, durability, and safety of MDF products depend not only on the wood fibers but also on the type and quality of adhesives used during manufacturing.

Adhesives such as urea, melamine, and melamine–urea copolymers play a critical role in MDF bonding strength and emission characteristics. However, identifying adhesive composition within finished MDF products is challenging using conventional analytical methods. This is where Evolved Gas Analysis–Mass Spectrometry (EGA-MS) provides a powerful and reliable solution.

In this technical study, EGA-MS is applied to analyze and differentiate adhesives used in MDF by examining their thermal decomposition behavior.

Background

In the previous note (PYA1-122E), the compositional analysis of the surface layer of medium-density fiberboard (MDF) was carried out by heart-cut EGA-GC/MS. In this note, the analysis of adhesive used in the MDF is described based on the results on evolved gas analysis (EGA-MS).

Experimental

The adhesive raw material (ARM) and two MDF samples (MDF1 and MDF2) were used for measurements. The solid ARM was prepared by evaporating water from an aqueous solution of urea, melamine (small amount), and formaldehyde at 120 ºC, where no condensation reaction occurred. MDF1 was molded at a high temperature by adding hardener etc. to the ARM, and MDF2 was a sample with unknown adhesive compositions. The entire surface of the each MDF sample was scraped off using a cutting knife and was placed in a sample cup.

All measurements were done using a GC/MS system with a Multi-Shot Pyrolyzer (EGA/PY-3030D) directly interfaced to the GC injector. A deactivated metal tube was used to connect the GC injector to a quadrupole MS, and the pyrolyzer furnace was heated up at 20 ºC/min from 100 ºC to 700 ºC to obtain EGA thermograms.

Results

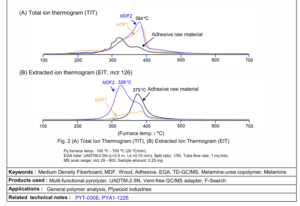

The total ion thermograms (TIT) of urea resin and melamine resin are shown in Fig. 1. Fig. 2 shows the (A) TIT and (B) extracted ion thermograms (EIT) of each sample. The EIT is drawn with m/z 126, which is characteristic of the melamine structure. In Fig. 2 (B), the EIT peak of the ARM at 375 ºC is ascribed to melamine (sublimation temperature 345 ºC), one of the constituents of the ARM.

The peaks and shoulders of MDF1 and MDF2 were also observed in the same temperature range, suggesting that they are originated from unreacted melamine or melamine added as a formaldehyde scavenger. On the other hand, the EIT peak temperature of MDF2 shifts to a lower temperature than that of melamine resin (about 380 ºC, Fig. 1) and the peak is broadened, probably due to the copolymerization of melamine and urea. In addition, the peak shape is close to a Gaussian distribution, suggesting that MDF2 has a better polymerization distribution, compared to MDF1. From the above results, it was found that EGA-MS was able to differentiate the melamine-urea copolymerization resins as well as to detect the melamine constituent.

To learn more about how EGA-MS and a multi-functional pyrolyzer can be used to analyze and differentiate MDF adhesives through thermal decomposition profiling, simply connect with us.

References: This technical note was developed by Frontier Laboratories Ltd. 4-16-20 Saikon, Koriyama, Fukushima, 963-8862 JAPAN. www.frontier-lab.com