Polyoxymethylene (POM) is widely used in mechanical components such as air pump parts due to its excellent sliding properties and dimensional stability. However, premature failure of POM components can occur when thermal degradation progresses faster than expected. Identifying the root cause of such failures is critical for quality assurance and product reliability.

Evolved Gas Analysis–Mass Spectrometry (EGA-MS) provides a powerful approach to evaluate the thermal stability and degradation behavior of polymer components. In this technical study, EGA-MS is applied to compare good and defective POM air pump parts that failed within a short service period. As a result, subtle differences in thermal decomposition behavior become clearly visible.

Background

Polyoxymethylene (POM) is a polymer composed of oxymethylene units (-O-CH₂-) and is widely used in bearings and other mechanical parts due to its excellent sliding properties. However, it is known that POM homopolymer is thermally depolymerized and easily degraded, and the mechanical parts are considered susceptible to frictional heat and other factors. To suppress the thermal depolymerization and improve the heat resistance, a small amounts of other monomers are copolymerized with POM, or the polymer chain is end-capped. In this report, evolved gas analysis (EGA)-MS was performed on a good and defective POM parts of an air pump that failed in a short period of time.

Experimental

The POM part (Fig. 1) removed from an air pump was cut into small pieces less than 1 mm in diameter with a cutter knife and used for measurements. A GC/MS system with a Multi-Shot Pyrolyzer directly interfaced to the GC injector was used for EGA-MS measurements. A deactivated metal tube and a vent-free GC/MS adapter were used to connect the GC injector to the MS detector.

Results

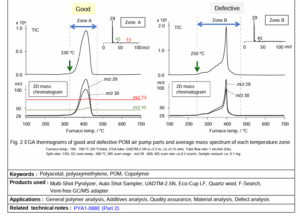

EGA thermograms of good and detective samples are shown in Fig. 2. In the good part sample, the rise of the peak is observed from 330 ºC. In the 2D mass chromatogram, peaks at m/z 45 and 73 are observed in addition to m/z 29 and 30, which are apparently derived from formaldehyde.

In the defective part sample, the rise of the EGA peak was observed from 250 ºC, which is lower than that for the good part sample. In the 2D mass chromatogram, only ions derived from formaldehyde were observed. More detailed analysis by pyrolysis-GC/MS will be reported in the note that follows (PYA1-088E).

To learn more about how EGA-MS can be used for defect analysis and thermal degradation evaluation of POM components, simply connect with us.

References: This technical note was developed by Frontier Laboratories Ltd. 4-16-20 Saikon, Koriyama, Fukushima, 963-8862 JAPAN. www.frontier-lab.com